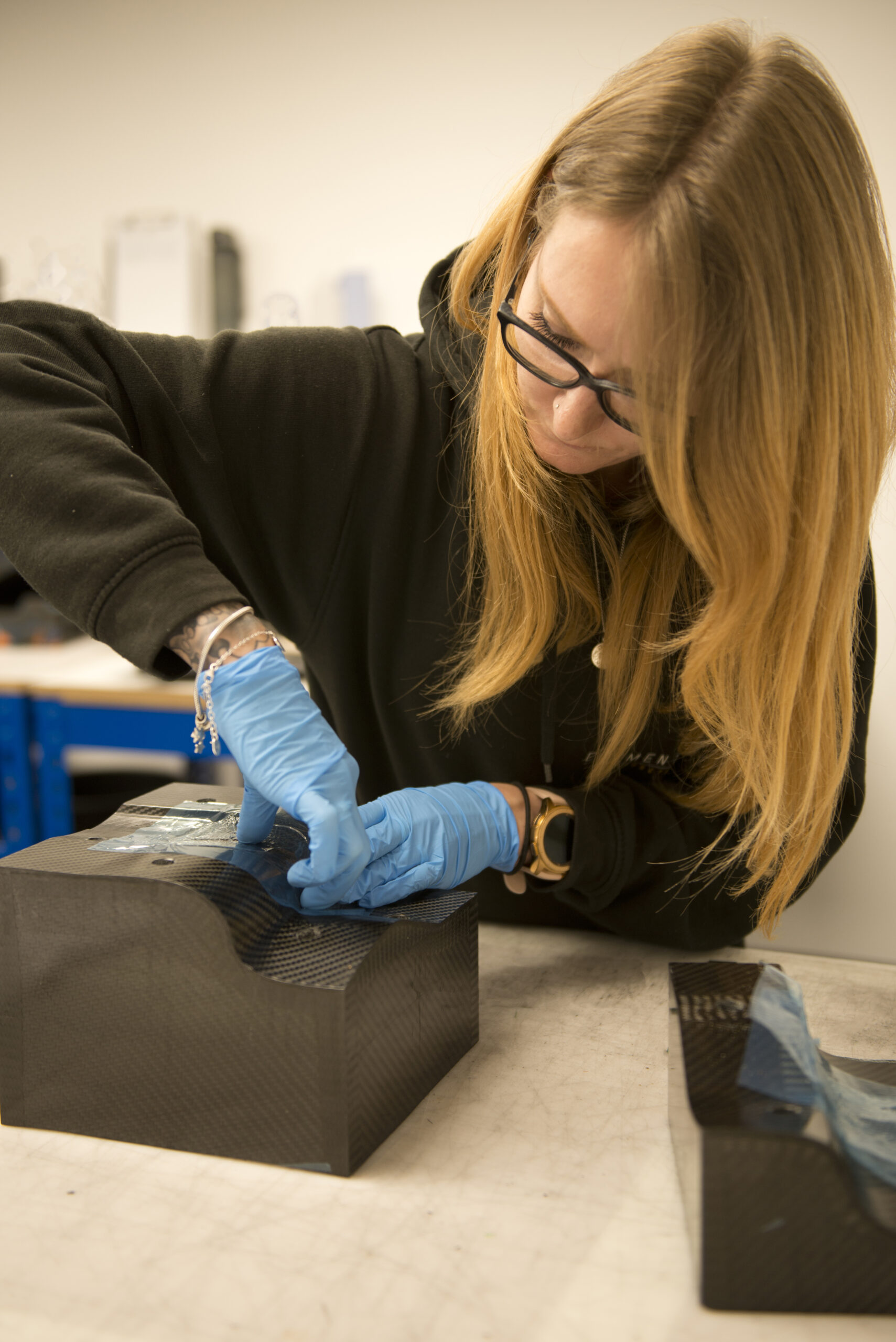

A prime example of our capabilities at Element 6 Composites Ltd. is our recent collaboration with a renowned coachbuilder specializing in converting vehicles into hearses and limousines. They approached us with a unique challenge: to transform the pressed steel and aluminium doors of an electric vehicle into a high-performance composite assembly.

Project Overview:

Client: Coachbuilder specializing in hearses and limousines

Objective: Replace traditional pressed steel and aluminium doors with a composite assembly for an electric vehicle conversion

Components: Rear tailgate assembly and door skins

Our Solution:

The client sought to achieve significant weight reduction without compromising on stiffness and form. Utilizing our advanced design and manufacturing capabilities, we developed a composite rear tailgate assembly and door skins that surpassed expectations.

Key Achievements:

Weight Savings: The composite rear tailgate boasts a weight reduction of over 70% compared to the original pressed steel and aluminium components.

Structural Integrity: Despite the significant weight savings, the composite assembly retained exceptional stiffness and form, ensuring durability and performance.

Customization: Our end-to-end service allowed us to tailor the composite components to the client’s exact specifications, seamlessly integrating with the vehicle’s design and functionality.

Conclusion: This successful collaboration underscores our expertise in providing innovative composite solutions for diverse applications. By replacing traditional materials with advanced composites, we not only achieved remarkable weight savings but also enhanced the overall performance and aesthetics of the vehicle.

At Element 6 Composites Ltd., we are proud to deliver cutting-edge solutions that drive efficiency, performance, and innovation for our clients across various sectors.