Top Benefits of Composite Materials in Automotive and Motorsports

When you enter the world of automotive and motorsports, the importance of improved performance, safety, and efficiency is relentless. Among the technological advancements driving these industries forward, composite materials stand out as a game-changer. The benefits of composite materials are vast, making them an essential component in modern vehicle design and manufacturing.

Composite materials, which are engineered from two or more constituent materials with significantly different physical or chemical properties, offer unique advantages over traditional materials like steel and aluminium. They combine the best qualities of their components to create a material that is lighter, stronger, and more durable. This transformative potential is why they are increasingly used in the production of high-performance vehicles.

In this blog, we will explore the numerous benefits of composite materials, particularly in the context of automotive and motorsports, and how they are revolutionising these industries. From weight reduction to enhanced durability and environmental sustainability, the advantages are compelling and worth understanding.

Understanding Composite Materials

Composite materials are a marvel of modern engineering, created by combining two or more different materials to produce a new material with enhanced properties. Typically, composites consist of a matrix (such as resin) and a reinforcement (such as carbon fibre). The matrix binds the reinforcement together, transferring loads and protecting it from environmental and mechanical damage, while the reinforcement provides strength and stiffness.

The versatility of composite materials lies in their ability to be tailored to specific requirements. By adjusting the types and proportions of the matrix and reinforcement, engineers can create composites that meet exact specifications for a wide range of applications. This adaptability is particularly beneficial in automotive and motorsports, where performance and reliability are paramount.

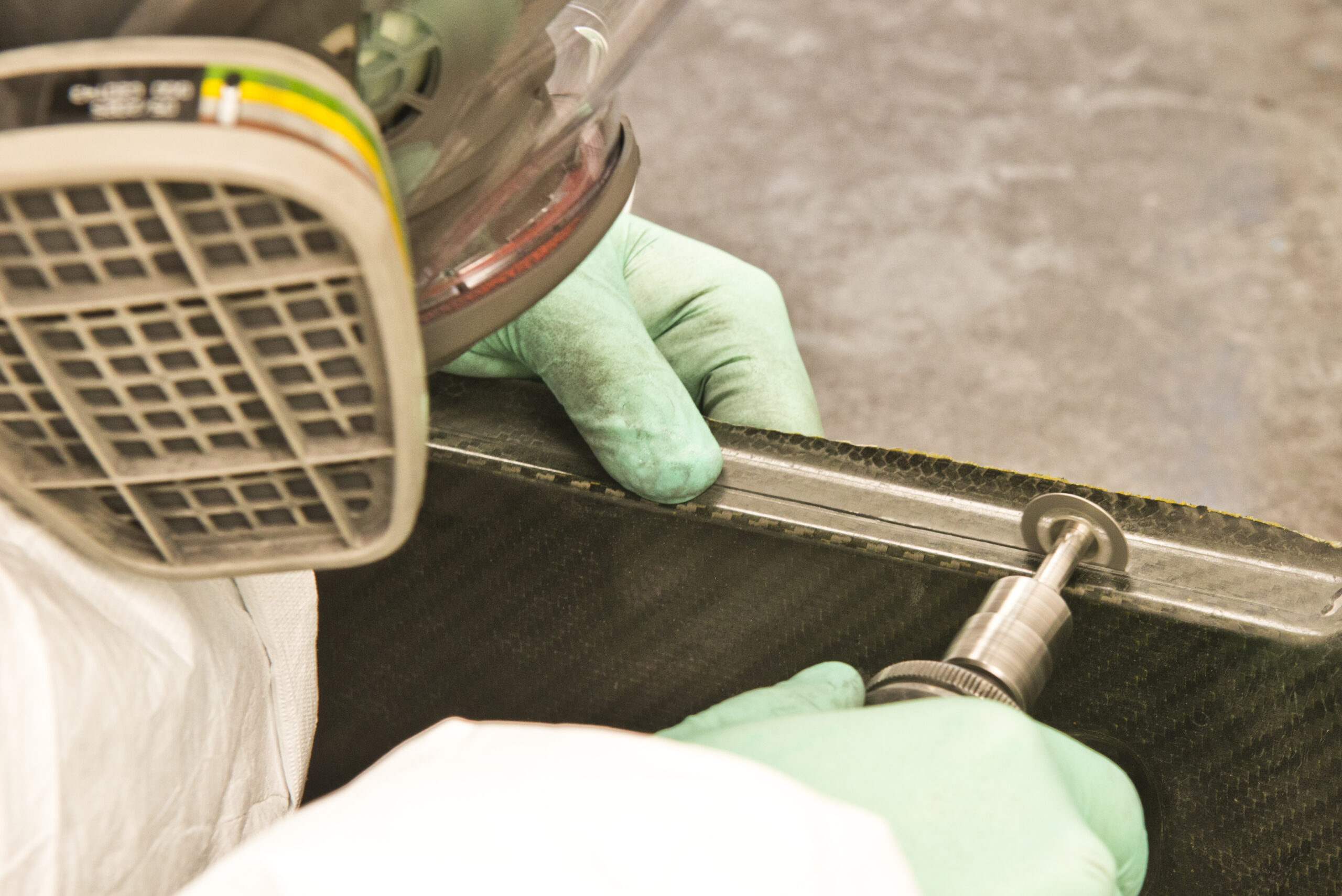

Carbon Fibre Reinforced Polymer (CFRP) is one of the most commonly used composite materials in these industries. CFRP combines the high strength-to-weight ratio of carbon fibre with the flexibility and durability of polymer resin, resulting in a material that is both lightweight and incredibly strong. This makes it ideal for constructing components that need to withstand extreme conditions without adding excessive weight.

Understanding the fundamentals of composite materials is crucial for appreciating their benefits.

The Role of Composite Materials in Automotive and Motorsports

Composite materials have revolutionised the automotive and motorsports industries, playing a pivotal role in the design and performance of modern vehicles. Their unique properties make them ideal for applications where high performance, durability, and weight reduction are crucial. Over the past few decades, the use of composite materials in these sectors has grown exponentially, driven by the constant pursuit of speed, efficiency, and safety.

In automotive manufacturing, composite materials are used in various components, from body panels and chassis to interior parts and engine components. Their ability to reduce weight without compromising strength and rigidity leads to significant improvements in fuel efficiency and overall vehicle performance. For example, the use of Carbon Fibre Reinforced Polymer (CFRP) in car bodies not only enhances the car’s structural integrity but also contributes to lower emissions due to improved fuel economy.

In the realm of motorsports, the benefits of composite materials are even more pronounced. Formula 1, for instance, heavily relies on composites for constructing everything from the monocoque chassis to aerodynamic components. The lightweight yet robust nature of composites allows race cars to achieve unparalleled speed and agility while ensuring the safety of the driver. Additionally, the flexibility of composite materials enables designers to create complex shapes and structures that optimise aerodynamic performance.

The integration of composite materials in automotive and motorsports is a testament to their transformative impact. By leveraging the advantages of these advanced materials, manufacturers can push the boundaries of innovation, creating vehicles that are faster, safer, and more efficient than ever before.

Weight Reduction and Performance Enhancement

One of the most significant benefits of composite materials in automotive and motorsports is their ability to drastically reduce weight while enhancing performance. Traditional materials like steel and aluminium, although strong, add considerable weight to vehicles. Composite materials, particularly Carbon Fibre Reinforced Polymer (CFRP), offer a superior alternative due to their high strength-to-weight ratio.

Reducing vehicle weight is critical in both automotive and motorsports for several reasons. Firstly, a lighter vehicle requires less energy to move, leading to improved fuel efficiency and reduced emissions. This is especially important in the context of stringent environmental regulations and the global push towards sustainability. Vehicles made with composite materials can achieve better mileage, making them more economical and environmentally friendly.

In motorsports, weight reduction is paramount for achieving optimal speed and handling. Lighter race cars can accelerate faster, brake more effectively, and navigate corners with greater agility. The use of CFRP and other composites in components like body panels, suspension parts, and even wheels helps reduce the overall weight of the vehicle without compromising on strength or durability. This weight savings translates directly into better lap times and enhanced competitive performance.

Moreover, the performance benefits of composite materials extend beyond just weight reduction. Composites offer superior stiffness and rigidity, which improves the structural integrity and safety of the vehicle. This is crucial in high-speed scenarios where maintaining control and stability is vital. Additionally, the flexibility of composite materials allows for innovative design possibilities. Engineers can create complex shapes and aerodynamic structures that enhance airflow and reduce drag, further boosting performance.

The combination of weight reduction and performance enhancement makes composite materials an indispensable asset in the automotive and motorsports industries. By leveraging these advanced materials, manufacturers can produce vehicles that are not only faster and more efficient but also safer and more environmentally responsible.

Durability and Strength

The durability and strength of composite materials are among their most compelling benefits, making them ideal for use in the demanding environments of automotive and motorsports. Unlike traditional materials such as steel and aluminium, composites like Carbon Fibre Reinforced Polymer (CFRP) offer exceptional resistance to wear, fatigue, and environmental factors, ensuring long-lasting performance and reliability.

Key advantages of composite materials include:

- High Strength-to-Weight Ratio: CFRP is significantly lighter than steel yet can be up to ten times stronger. This remarkable strength is crucial for components that must endure high stresses and impacts, such as chassis, suspension parts, and body panels.

- Superior Fatigue Resistance: In the automotive and motorsports industries, vehicles are subjected to repeated loading and unloading cycles, which can cause metal components to weaken and fail over time. Composites, however, maintain their structural integrity even after prolonged exposure to cyclical stresses, leading to increased safety and reliability.

- Excellent Corrosion Resistance: Unlike metals, which can rust and corrode when exposed to moisture and chemicals, composites are inherently resistant to these factors. This makes them particularly suitable for use in harsh environments, such as marine applications or areas with extreme weather conditions.

Additional benefits:

- Enhanced Longevity: The durability of composites ensures that vehicle components can withstand the rigours of high-speed racing and everyday driving without degrading over time, reducing the need for frequent replacements and maintenance.

- Improved Safety: Composite structures can absorb and dissipate energy more effectively than metal counterparts in the event of a collision, providing better protection for occupants. This capability is vital in motorsports, where safety is paramount, and in consumer vehicles, where crash safety standards are increasingly stringent.

The exceptional durability and strength of composite materials make them a cornerstone of modern automotive and motorsports engineering. By utilising these advanced materials, manufacturers can create vehicles that are not only high-performing but also safe, reliable, and built to last.

Environmental Benefits of Composite Materials

The environmental benefits are increasingly recognised as industries strive for sustainability. Composite materials, particularly Carbon Fibre Reinforced Polymer (CFRP), offer significant advantages in reducing the environmental impact of automotive and motorsports manufacturing and usage.

Firstly, the lightweight nature of composites directly contributes to improved fuel efficiency in vehicles. By reducing the overall weight, vehicles require less energy to operate, leading to lower fuel consumption and reduced greenhouse gas emissions. This is a crucial step towards meeting stringent environmental regulations and achieving global sustainability goals.

Moreover, the durability and longevity of composite materials mean that components made from these materials require less frequent replacement. This reduces the demand for raw materials and energy associated with manufacturing new parts, thereby decreasing the overall environmental footprint. The resistance of composites to corrosion and environmental degradation further extends their lifespan, making them an eco-friendly choice for long-term use.

Additionally, advancements in composite recycling technologies are enhancing the environmental benefits of these materials. While recycling composites has been challenging, new methods are being developed to efficiently reclaim and reuse fibres and resins. This progress is vital for creating a circular economy where materials are continuously repurposed, reducing waste and conserving natural resources.

Cost Efficiency in the Long Run

While the initial cost of composite materials such as Carbon Fibre Reinforced Polymer (CFRP) may be higher than traditional materials, their long-term cost efficiency makes them a wise investment for the automotive and motorsports industries. The benefits of composite materials extend far beyond their purchase price, offering substantial savings over the lifespan of a vehicle.

One of the primary cost-saving factors is the reduced need for maintenance and replacement. Composite materials are highly durable and resistant to corrosion, wear, and environmental damage. This longevity means that components made from composites require less frequent repairs and replacements compared to those made from metals like steel and aluminium. Consequently, maintenance costs are significantly lowered.

Furthermore, the weight reduction achieved with composite materials leads to improved fuel efficiency. Lighter vehicles consume less fuel, which translates to ongoing savings in fuel costs. For fleet operators and individual vehicle owners alike, this can result in considerable financial benefits over time.

Additionally, the superior performance and safety features of composite materials can lead to indirect cost savings. For example, enhanced crash safety can reduce injury-related expenses and insurance premiums. The improved performance can also contribute to better resale values for vehicles, providing further financial advantages.

Future of Composite Materials in Automotive and Motorsports

The future of composite materials in automotive and motorsports is incredibly promising. As technology advances, the development of even lighter, stronger, and more versatile composites is on the horizon. Innovations in recycling processes and sustainable production methods are expected to make composite materials even more environmentally friendly, aligning with the global push towards sustainability.

In motorsports, ongoing research aims to enhance the performance characteristics of composite materials, enabling even faster and safer vehicles. For the automotive industry, the integration of smart composites with embedded sensors could revolutionise vehicle monitoring and maintenance.

At E6 Composites, we are committed to staying at the forefront of these advancements. Our expertise and state-of-the-art facilities ensure that we can meet the evolving needs of our clients. If you’re interested in learning more about the benefits of composite materials or need high-quality composite components for your project, please contact us at 01243 530831 or email us at admin@e6composites.co.uk. Let us help you drive innovation in your industry.